CASE STUDY: Removal of Pharmaceutical Residues and APIs

A comprehensive removal of APIs of >90% and often to below LOD (the limit of detection).

Probably the biggest problem facing policymakers tackling pharmaceuticals in the environment (PiE) is that they are invisible. If it is difficult to persuade people that they should change age-old practices and make costly investments. It is even harder when they cannot see the evidence in the short-term.

Sources of PiE are wide-ranging and include:

* Human excreta collected at sewage treatment plants and arising in effluent;

* Unused drugs disposed to landfill waste streams later emerging in leachate;

* Pharmaceutical manufacturing plant wastewater discharge (often containing Active Pharmaceutical Ingredients (APIs));

* Animal excreta from intensive farming appearing in run-off;

* Meat production, abattoir and rendering plant discharge.

Irais Baizabal

Wastewater consultant

Schedule a call with one of our wastewater treatment consultants at your convenience. Or you can send us an enquiry.

This case study includes data from two clients:

1. DOC2C’s consortium, Europe

A collaboration with project partners from the water industry and universities in the 2 Seas Area to research and exchange the results on contaminant removal.

2. Nersingen City Council, Germany

A reduction of a mix of pharmaceutical residues from municipal water at the tertiary stage.

Pharmaceutical company, US

In both cases, the Nyex Rosalox treatment system was deployed on wastewater containing a cocktail of antibiotics, anti-inflammatories, beta and nerve blockers as well as anti-depressants, amongst other regularly administered medications.

The Nyex Rosalox treatment process combines adsorption with electrochemical oxidation in a single, scalable unit, without the production of sludge. Unlike activated carbon, Nyex™ media is effectively regenerated in-situ and the process can continue without interruption or incineration.

The treated water then flows from the reactor tank ready to be safely discharged.

Tell us what organic compounds you need to remove from your water and our consultants will give their recommended approach which might involve:

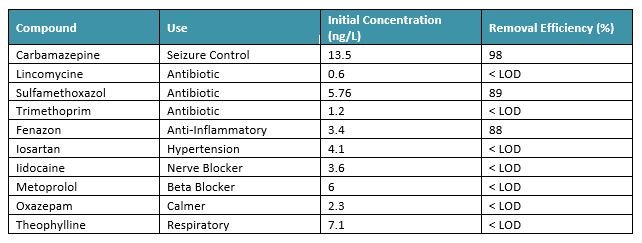

Figure 1 – Results from the on-site trials show a comprehensive removal of various pharmaceutical contaminants of >90% and often to below the limit of detection (LOD). The waters tested were surface water from Ijssel Meer and brine from both an ion-exchange and an electrodialysis unit.

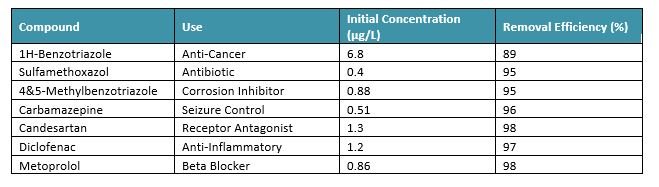

Results from the in-house trials at Arvia’s facilities on real samples of water from Nersingen demonstrate a comprehensive removal rate against various pharmaceutical contaminants. Analysis was provided by an external laboratory for the raw water pre and post-treatment

Acknowledgements – *The DOC2C’s consortium consists of PWN Technologies R&D (NL), South West Water (UK), De Watergroep (BE), Lille University (FR) and Delft University of Technology (NL).

03.3.2023

Case study shows how our Nyex Ellenox system achieved over 99% removal rate of Triton X 100 (4-tert-OPnEO) from pharmaceutical wastewater.

03.3.2023

A pharma company asked us to help them stop the spread of AMR by removing APIs and COD from wash water.

03.3.2023

"Arvia's technology is innovative and has been proven to solve our waste issue."

Life sciences

We remove APIs and hard-to-treat micropollutants from wastewater for pharma, CDMOs, animal health, biotech and biopharma sectors.

Speciality Chemicals

We help specialty chemical companies clean their process water, removing active ingredients, biocides, recalcitrant COD and micropollutants.

Agrochemicals

Our industrial wastewater treatment process is very effective in removing organic chemicals such as pesticides, herbicides and insecticides.

Manufacturing

We provide industrial wastewater treatment solutions removing biocides and other micropollutants in wash water and blowdown water.

Aquaculture

Our aquaculture wastewater treatment removes pesticides used to treat sea lice, as well as medicines and off-flavours found in RAS facilities.