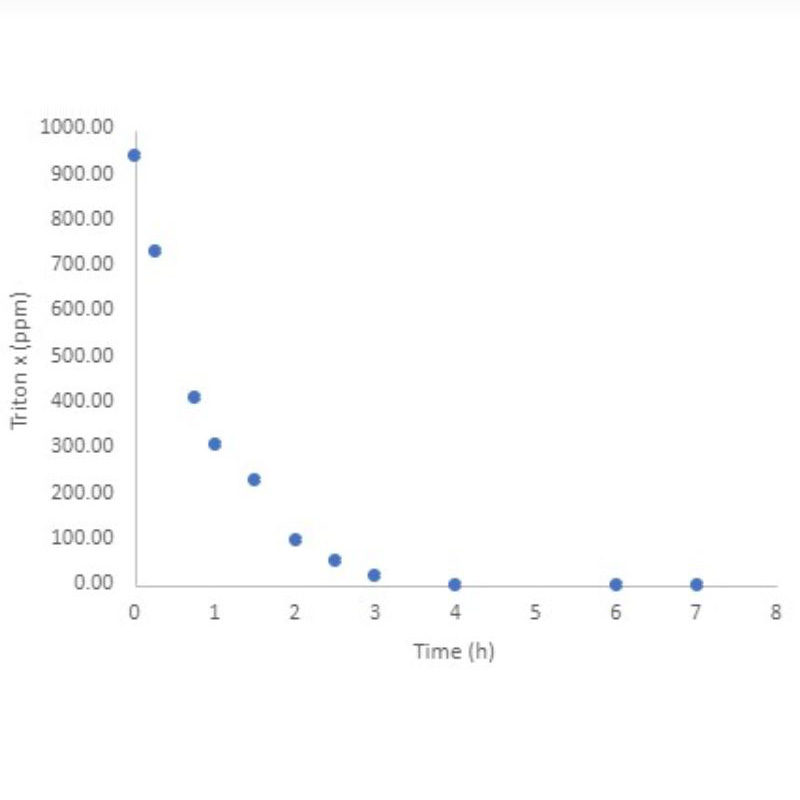

Case Study: 4-tert-OPnEO Removal from Wastewater

Triton X-100 otherwise known as octylphenol ethoxylate or 4-tert-OPnEO is a non-ionic surfactant that belongs to the substance group 4-(1,1,3,3-tetramethylbutyl) phenol, ethoxylated. This case study details our proven water treatment process which removes Triton X 100 to trace levels, avoiding the need for wastewater incineration.