Removal of PAHs from Chemical Wastewater

The Nyex™ range of wastewater treatment technologies are well suited for the final removal of persistent organic contaminants such as PAHs.

Polycyclic Aromatic Hydrocarbons (PAHs) are toxic to the human body and can cause a range of respiratory and cardiovascular disorders. Industries which produce PAHs in their wastewater are fully aware of the dangers and often come to us requesting help.

A sustainable solution for their removal, without chemical dosing or the production of secondary waste is in high demand. Our water treatment processes are designed to reduce persistent organic compounds to trace levels.

Jerome Budin

Wastewater consultant

Schedule a call with one of our wastewater treatment consultants at your convenience. Or you can send us an enquiry.

A chemical company approached Arvia to help them remove PAHs (Poly Aromatic Hydrocarbons) from their wastewater.

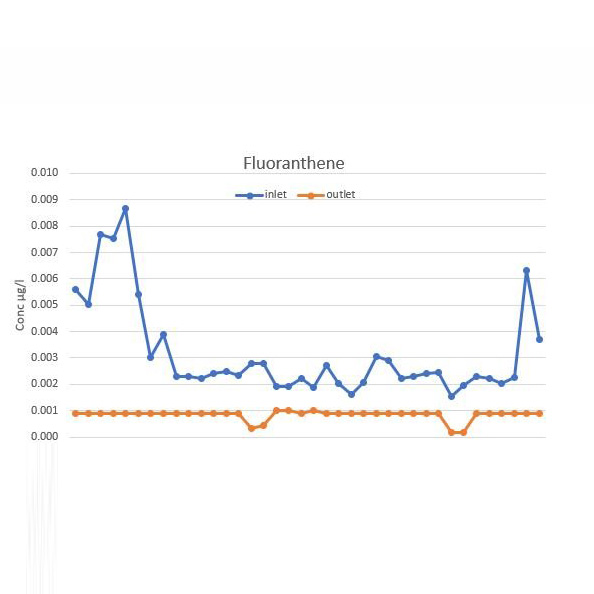

There were two specific PAHs which needed to be reduced. These were fluoranthene and the most well known PAH, benzo(a)pyrene, also known as BaP. This chemical is understood to cause cancer in humans and is found in oil and gas wastewater as well as tobacco smoke and in toasted food.

Both chemicals are hazardous in water and we were asked to use our water technology to reduce the PAHs levels.

Pharmaceutical company, US

The concentrations of the PAHs were in the µg/L range so the Nyex™-a system was selected. This process overcomes mass transport limitations. The combination of adsorption with electrochemical oxidation in the Nyex™-a system means treatment is targeted to the localised (adsorbed) contaminant, where the highly reactive hydroxyl radicals are produced.

Fluoranthene was treated from a live wastewater stream over a 9-month period, achieving an average of >68.3% removal as evidenced in the adjacent graph.

Tell us what organic compounds you need to remove from your water and our consultants will give their recommended approach which might involve:

03.3.2023

Nyex was chosen over Ozone and Fenton due to reduced OpEx and lack of sludge.

03.30.2021

>99% reduction in phenol allowed safe discharge.

05.9.2023

Case study shows how our Nyex Ellenox system achieved over 99% removal rate of 1,4-dioxane from industrial wastewater

Life sciences

We remove APIs and hard-to-treat micropollutants from wastewater for pharma, CDMOs, animal health, biotech and biopharma sectors.

Speciality Chemicals

We help specialty chemical companies clean their process water, removing active ingredients, biocides, recalcitrant COD and micropollutants.

Agrochemicals

Our industrial wastewater treatment process is very effective in removing organic chemicals such as pesticides, herbicides and insecticides.

Manufacturing

We provide industrial wastewater treatment solutions removing biocides and other micropollutants in wash water and blowdown water.

Aquaculture

Our aquaculture wastewater treatment removes pesticides used to treat sea lice, as well as medicines and off-flavours found in RAS facilities.