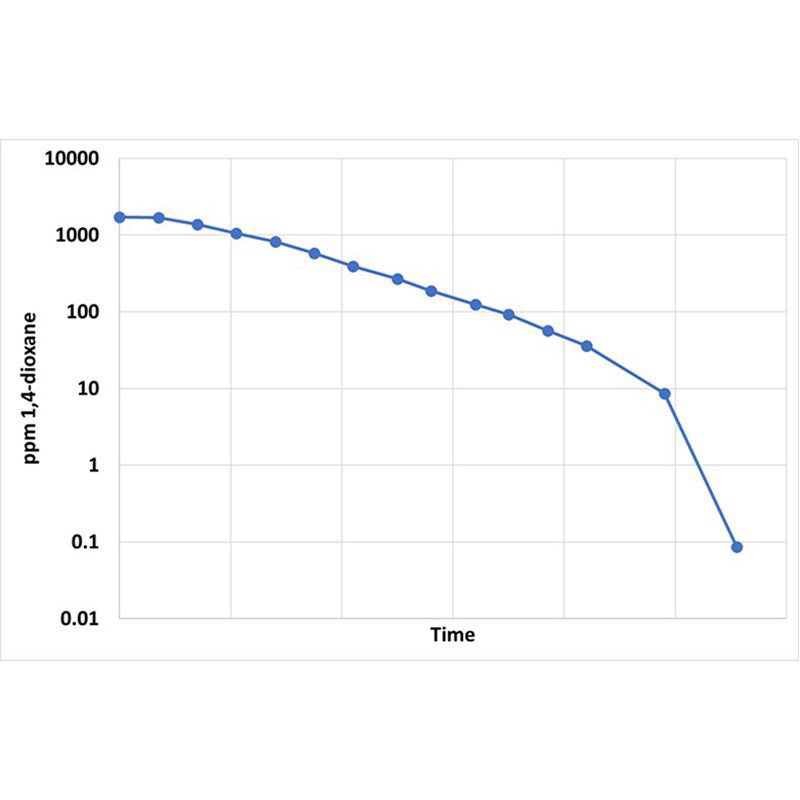

Case Study: Remove 1,4-Dioxane from Water

1,4-Dioxane is an organic contaminant which can be found in small trace amounts in some cosmetic products. The chemical is a by-product of some chemical manufacturing processes. This case study detail how our proven water treatment technology removes 1,4-Dioxane to trace levels.