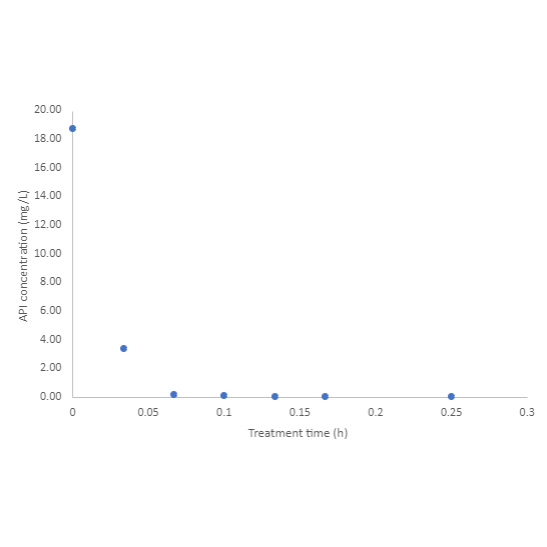

Our solution: Removal of APIs from pharma water

We deployed the Nyex Rosalox™ treatment system in order to tackle the containing the API containing wastewater. This was a compact and fully automated solution.

Arvia’s solution provided a <2 year ROI.

Technology alternative was a Multiple Effect Evaporator (MEE). Arvia’s solution was ¼ of MEE capital cost. MEE was a higher OPEX solution too.

The Nyex Rosalox™ treatment process combines adsorption with electrochemical oxidation in a single, scalable unit. As the contaminated water flows into the reactor tank, pharmaceutical contaminants are concentrated onto the surface of our proprietary Nyex™ adsorbent media, which is non-porous with high electrical conductivity.

A low electrical current is simultaneously passed through the media bed to fully mineralise the adsorbed contaminants to H₂O, H₂ and CO₂, without the production of sludge. Unlike activated carbon, Nyex™ media is effectively regenerated in-situ and the process can continue without interruption or incineration to renew the media.

The treated water then flows from the reactor tank ready to be safely discharged.

How this works